Pengqiang Technology Intelligent Group, focusing on the production of the auxiliary machine in various rubber and plastic machinery and other industrial production needs. One of our production Volumetric Doser plays a very important role in the injection molding industry, and the use of the Doser is the most basic and important production link in the rubber and plastic industry.

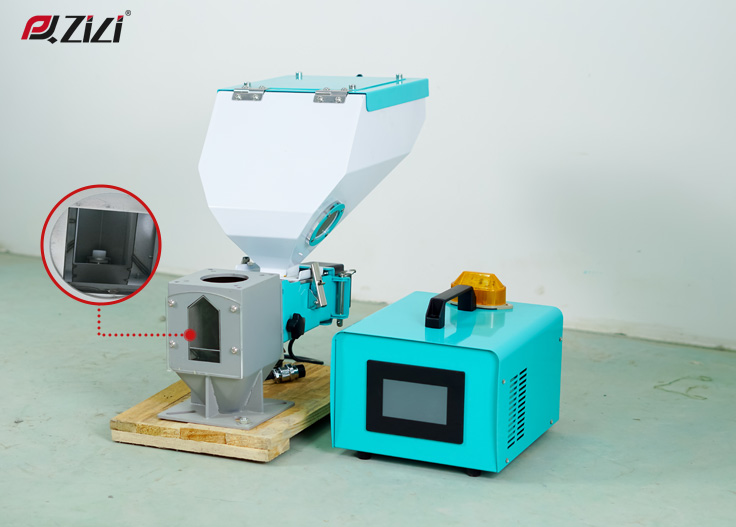

The Volumetric Doser is suitable for injection molding, extrusion or blow molding production, and is used for automatic proportional mixing of new and secondary materials, masterbatches or additives.The measuring type of the machine uses DC brushless motor to mix according to the pre-set ratio, and through the full digital microcomputer control system to set the conditions automatically converted to rotational speed to directly drive the precision screw to extrude the raw materials.

Our company produces both two-color Doser and single-color Doser. The working principle is the same, while the role and the price is different. You can choose the suitable one based on your own needs.

The Dosers produced by Pengqiang Group is transmitted to the motor of the machine through the signal from the control box. When the motor starts to rotate, the screw of the machine will be driven to rotate through the coupling.

At the same time, the masterbatch in the hopper is affected by the rotation and starts to fall into the screw. After being squeezed by the screw, it is transported to the base, so as to achieve the purpose of precisely measuring and transporting the masterbatch.

Direct dosing and mixing of masterbatch, additives or re-materials often requires excellent mixing quality and high repeatability in order to maintain the consistency of product color and quality as much as possible.

4. Raise the temperature of the machine appropriately, which can increase the brightness of the products, and also apply back pressure to the Volumetric Doser appropriately, which can improve the mixing effect of the screw, and is conducive to the dispersion of the pigment.

However, applying back pressure has a little side effect, that is, the speed will be slowed down in the process of injection molding.

|

|

Single&Double Screw Volumetric Doser Specification with Mixer |

|||||

|

Model |

PQ-ZL16S |

PQ-ZL20S |

PQ-ZL25S |

PQ-ZL16D |

PQ-ZL20D |

PQ-ZL25D |

|

Power |

220V 1N 50HZ |

|||||

|

Motor Power(W) |

86 |

86 |

86 |

86*2 |

86*2 |

86*2 |

|

Rotary Speed (r.p.m.) |

360 |

360 |

360 |

360*2 |

360*2 |

360*2 |

|

Mixer Power(W) |

40 |

40 |

40 |

40*2 |

40*2 |

40*2 |

|

Screw Dia (MM) |

16 |

20 |

25 |

16 |

20 |

25 |

|

Storage Capacity(L) |

12 |

12 |

12 |

12*2 |

12*2 |

12*2 |

|

Output Capacity(KG/H) |

0.72~7.2 |

1.4~14 |

1.9~19 |

0.72~7.2*2 |

1.4~14*2 |

1.9~19*2 |

|

Gear Ratio |

1:35 |

1:35 |

1:35 |

1:35 |

1:35 |

1:35 |

|

Whole Machine(CM) |

57*57*28 |

57*57*28 |

57*57*28 |

57*99*28 |

57*99*28 |

57*99*28 |

|

Net Weight(KG) |

27 |

27 |

27 |

38 |

38 |

38 |

Name: Mr.Taylor Jiao

Mobile:8617818941386

Tel:8617818941386

Whatsapp:8617818941386

Email:taylor_jiao@pqzili.com

Add:ZoneD first floor, building 3 Xinwei villagers group workshop shanpi village,lilin Town Zhongkai high tech Zone Huizhou City Guangdong China 516006