In the injection molding industry, the mold temperature controller is very important. The mold temperature controller can ensure the melting temperature and flow speed of the plastic in the production of the product, so as to ensure the shape of the product. And our company can provide the most important mold temperature controller (water temperature controller, oil temperature controller) in the production of plastic products.

The existence of the mold temperature controller can accurately control the mold temperature, provide very precise temperature control function, and ensure that each product can be evenly heated during the production process. In addition to ensuring product quality, the mold temperature controller can also shorten the product molding cycle, improve production efficiency, reduce product failure rate, and save production costs.

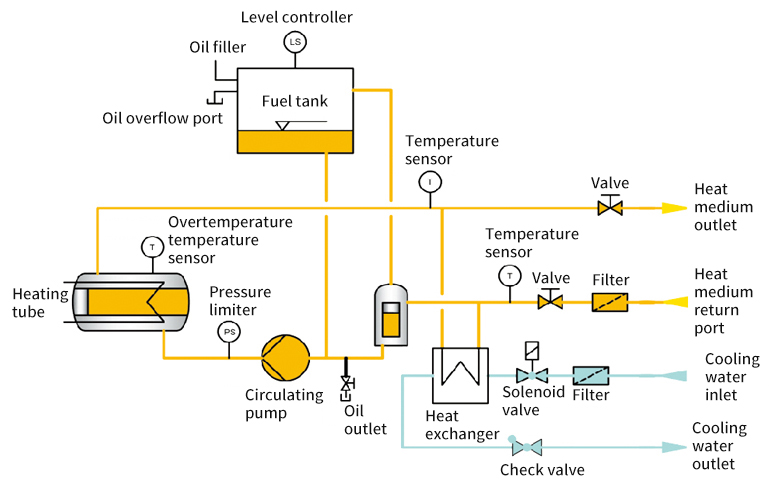

The working principle of the mold temperature machine is that the pump in the power transmission system makes the thermal fluid reach the mold from the water tank with built-in heater and cooler, and then returns from the mold to the water tank; the temperature sensor measures the temperature of the thermal fluid and transmits the data to the controller of the control part; the controller adjusts the temperature of the thermal fluid, thereby indirectly adjusting the temperature of the mold.

During the production process, if the temperature of the mold exceeds the set value of the mold temperature controller, the controller will open the solenoid valve and connect the water inlet until the temperature drops to the set value. If the mold temperature is too low, the controller will turn on the heater to heat the mold.

Injection Molding In The Automotive Industry:The production of auto parts often requires the participation of mold temperature machines, because auto parts need to use high-performance plastic materials and can withstand high temperature and high pressure environments. The use of mold temperature machines can just meet the production needs of auto parts and allow products to achieve the best performance in the production process.

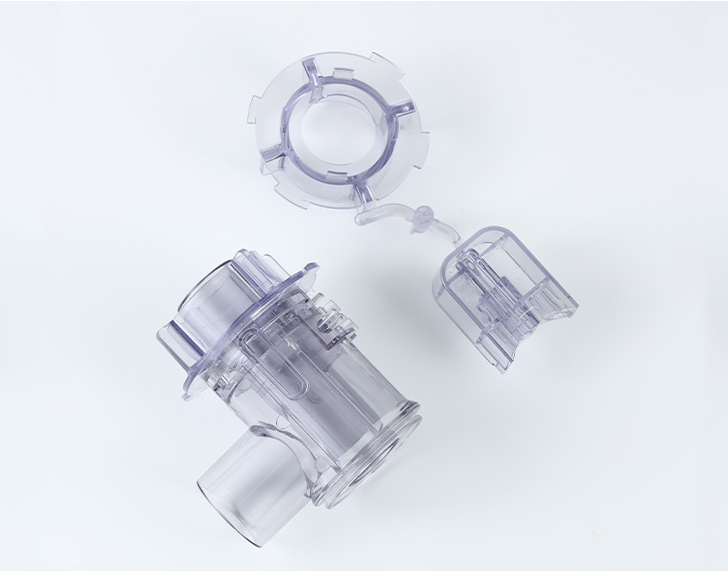

Injection Molding Of Medical Devices:As we all know, the materials used in the medical industry must have very high precision requirements, and the production of these products requires a mold temperature controller to control the temperature, so as to control the subtle changes in the molding process to ensure the quality of the final product.

Injection molding of electronic products:The casings of computers, mobile phones and other electronic products we use in our daily life often require high-precision molding to fit with other components. Using a mold temperature controller can make the temperature of the mold more stable, so as to control the fluidity and solidification speed of the material during the injection molding process.

Choose according to the demand and scale of your own production equipment. If the production scale is large and the output is large, you need a mold temperature controller with a relatively large power. On the contrary, you need to choose a mold temperature controller with a low power. Factors to be considered include: production environment, mold size, production materials, production volume, and required temperature control accuracy.

Intelligent: Our existing mold temperature controllers are controlled by intelligent microcomputers. In the future, our mold temperature will have more intelligent functions, such as automatic temperature control, data analysis, etc., to improve production efficiency and optimize the production process.

Efficiency: In the future, our mold temperature controllers will become more efficient, such as faster heating, more precise temperature control, etc., to improve production efficiency and reduce production costs.

Energy saving and environmental protection: From the perspective of power consumption, it is possible to produce a frequency conversion operating system. In terms of technology, it may be possible to adopt a more energy-saving cooling and heating integrated system to reduce energy consumption and environmental pollution.

The mold temperature controller is one of the essential equipment in the injection molding industry. Through the control of the temperature, the production efficiency and product quality can be improved, making the product more stable. Our company will also produce customized products according to customer needs, and strive for excellence to improve the technical content of the products.

Name: Mr.Taylor Jiao

Mobile:8617818941386

Tel:8617818941386

Whatsapp:8617818941386

Email:taylor_jiao@pqzili.com

Add:ZoneD first floor, building 3 Xinwei villagers group workshop shanpi village,lilin Town Zhongkai high tech Zone Huizhou City Guangdong China 516006